Instant notification; these are notifications that are instantly received on your smartphone, tablet or computer.

Nowadays, accessing information quickly has become almost as important as information. Access to information at home, at work, on the street, wherever you can think of, has started a new era. The most popular technologies of today, smartphones are the means of accessing this information quickly. The importance of instant notifications that inform the user about the types of events experienced on the machine is increasing day by day. Because there is a rapid evolution from technologies that inform via vibration when e-mail arrives, to push notifications in smart TVs and even wearable technologies.

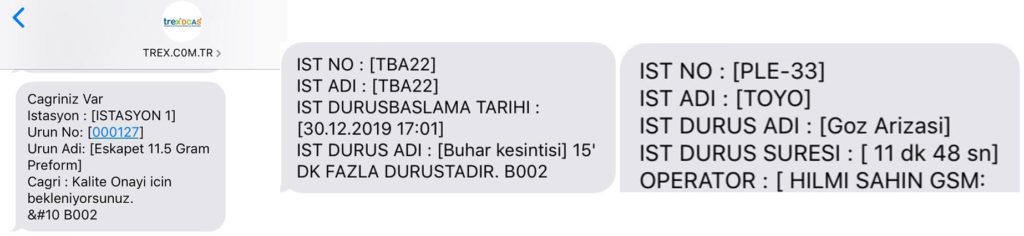

As trexDCAS, we send instant notifications to the management and necessary personnel at the right time for many situations (shift changes, new work starts, changes in performance values, OEE changes, quality controls, etc.) depending on the types of events experienced in the machines. These notifications can add one more point to the instant action conversion section. At the same time, you get the chance to improve the quality of your product.

By directing the notifications correctly, it helps companies to position themselves correctly and take the right steps quickly. Regardless of the sector of the company, the results of time sensitive push notifications will be very effective for you.

One of the biggest features of MES Systems is monitoring production processes in real time. In order to underline the real-time concept, MES Systems must keep up with today’s fast life. MES Systems, which monitors production processes and all machine resources in real time, are expected to transfer the data to authorized and responsible personnel in real time. Of course, what kind of push notification methods can be used as asked here? The following notification methods are common and more economical.

The E-Mail method is also a method that can be used if necessary.

Receiving notifications about the situations experienced in the machines concerns the factory management, the planning department, the maintenance department and the quality department shift supervisors and almost every department. It provides the opportunity to share instant information with the necessary units about new planning and emergency alerts that will make decisions such as planning changes, operator information, repair work orders.

With SMS and mail alert services, users can easily create their templates according to the conditions they want. Each company using it can send the mail alert with the e-mail information defined in the system as desired. After completing the system with an SMS package to be received, SMS sharing can be made instantly.

In fact, every data collected theoretically can be transformed into meaningful reports and sent as an instant notification to the person or people who need to be aware. So there is no limit to the question of what kind of notifications are made.

However, the most requested data or reports in the form of notification can be given as follows:

Stoppages, especially the types of downtimes we call unplanned stoppage, are one of the most demanded data.

The biggest advantage of sending instant notifications, first of all, will greatly increase the rate of panel usage.

The instant alert is a very effective tool that can help you improve the feedback faster. Of course, if it is used effectively. Regardless of the sector of the company, the results of time sensitive push notifications will be very effective for your company.

When instant notifications are used correctly, they can contribute to strengthening the connection between the user and the application. For this, it is important to analyse the user data well and to make a good planning, to create the right notifications with the right templates. It is a good approach to see the mistakes made in the machine.

Instant notifications help to take action on the status of the machine when the data is shared with the reminder notification via the sent alert reports.

The delivery of instant notification to the necessary people helps to take the necessary action by making the necessary analysis afterwards. They ensure that you always keep the use of the machine alive.

If you manage your push notifications correctly, your application will be able to share a new and important development at any time, and help to get the necessary improvements quickly.

The answer would be yes.

The elimination of losses should be the main goal in every field where productivity increase is aimed.

By analysing the data coming from the push notification, it is possible to identify and eliminate or improve the main cause. Since this improvement is an improvement to the machine, its effect on efficiency is inevitable.

With notifications;

Outgoing warning SMS and e-mails will have an effect on the reduction of downtime, correction of product cycle times within the delivered reports, correction of product quantity controls for stock, thus increasing productivity.

Of course, the notification settings screen has to offer users wide customization options. Because every sector has its own specific focal points. Production processes and data types that will increase production quality may differ. A company producing automotive spare parts and a company producing beverages or food cannot be expected to look at the same data. For this reason, a flexible MES system that can adapt to all sectors offers its users a wide range of customization options. First of all, the notification definition feature of the user must be based on authorization. In other words, every MES system user should be able to define a notification for the data they are authorized to see.

The user should be able to choose the method they want to receive notifications.

It is very difficult to predict which technologies will enter our lives in the future. 15 years ago, we did not know that smart mobile phones would be an indispensable part of life. We cannot predict which devices will enter our daily life 15 years from now. However, this question can be answered by considering that the use of technologies that are in their infancy or that have not yet become widespread due to their total costs will increase.

1-Artificial intelligence and machine learning

2-VR / Virtual Reality glasses

How can these 2 technologies contribute to the efficiency of MES Systems? All push notification methods take place after the desired notifications reach the limits or after a problem occurs. For example, if my OEE value falls below 75, you can send me a notification or send me a notification when my machines stop.

Through artificial intelligence and machine learning technology, the problems will be solved before the start by sending notifications to the relevant and responsible people before these things happen. Now, before your OEE value reaches the minimum level you want to receive notifications, all signals will be analysed by artificial intelligence and you will be notified beforehand. Through the machine learning, it can be learned with instant notifications that maybe the machines will fail within the specified time before they break down. Our R&D studies on this subject are continuing.

It is not difficult to predict that VR or virtual reality glasses will be used effectively in the industry when these technologies become accessible.

Through a VR glasses, detailed 3D modelling of factories can be done and you will be able to walk around the factory even if you are outside. The data collected from MES systems will also be displayed on the glasses. In this way, at a workstation, you will be able to see which work order is currently in production, completed and remaining values by simply looking at it, regardless of any device.

When you look at the special QR barcodes to be affixed on the machines with virtual reality glasses, we will have the chance to see all the data of that machine, its performance, the produced part, the completed quantity and similar information. In other words, instead of receiving instant notifications, it will come to a point where it can instantly see the desired data, regardless of location.